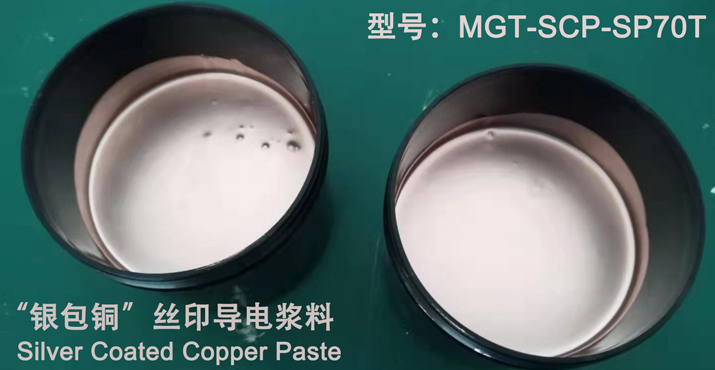

Product Description

Silver coated copper paste (Model: MGT-SCP-SP70T)has strong printing adaptability, single component, rapid curing at medium temperature, excellent adhesion, suitable for screen printing process. The product mainly used in circuit, circuit board, silicon chip, glass conductive circuit and other electronic fields. It's suitable for PC, PET, ABS, silicon wafer, glass and other substrates.

Product Features

● Strong printing adaptability

● Good electrical conductivity

● Excellent oxidation resistance

● Excellent adhesion

Product usage andprecautions

1. The viscosity of the system is very sensitive to the diluent ( DBE ). If dilution is needed, pleasedo not add more than 5% and add a very small amount of test step by step, and use as much as possible after opening it.

2. Blender for 3~5 minutes,mix manually at low speed for about 10 minutes, and be careful not to bring in air bubbles.

3. It is recommended to use 150 to 250 mesh polyester screen.

4. Suggestedbaking condition is 80~100℃ for 20~30min. The drying temperature should not exceed 130℃,do not bake for a long time to avoid oxidation.

5. Thesilver copper paste should be stored at 5~25℃and sealed in a cool place, shelf life is 3 months.

6. Diluter : less than 5% DBE or Diethyleneglycol monobutyl ether ( DB).

7. Screen cleaning solvent : Ethyl acetate or itsrelated solvents .

Remarks: silver content, solid content, conductivity and viscosity can be customized according to the actual needs of customers.

Disclaimer: The information provided in this Technical Data Sheet (TDS) is compiled ingood faith and obtained using procedures performed at Mogreat Company and to the best of our knowledge. The information on this TDS has been updated on the date printed, and latest versions can be obtained upon request. The customer is responsible for conducting tests to determine whether our products are compatible with the customer’s process and specific applications.

URL: www.mogreat.com