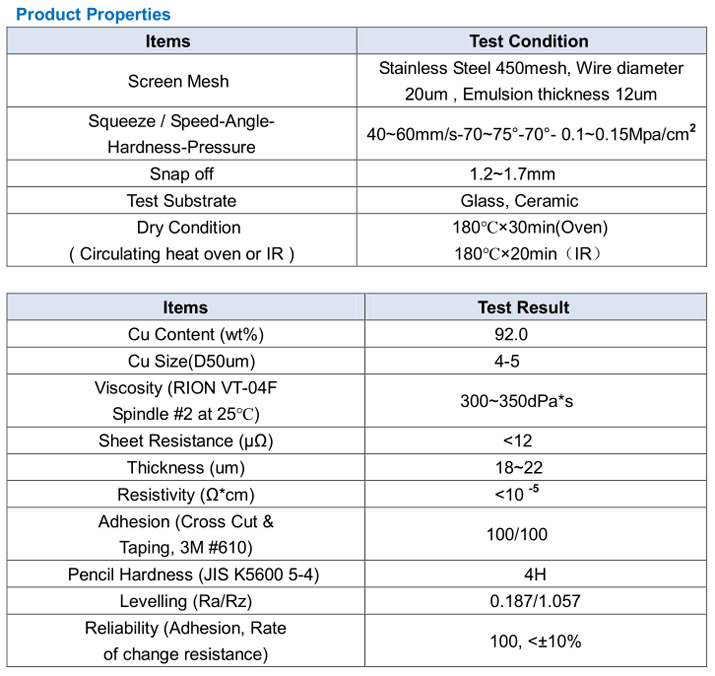

Product Description

Silver coated copper paste (solderable type) is a conductive pastefor electronic devices of solar energy. it has excellent adhesion and durability on glass and ceramic. The paste has high resolution on Glass, ceramic, PP, PI, Epoxy Resin, PA6, PPA, PET ITO, AgNW, PC substrates by using screenprinting process. It can maintain the typical properties after prolonged high humidity and temperature.

Product usage andprecautions

(1) The paste should be sealedand keep in dark place, storage temperature ≤0℃.

(2) Product shelf life is 5 months under the suggested storage conditions.

(3) Open it and stir well to use and no dilutionis required.

(4) Requirement for ambient temperature control:22±2℃

(5) Requirement for ambient humidity control:60±5%

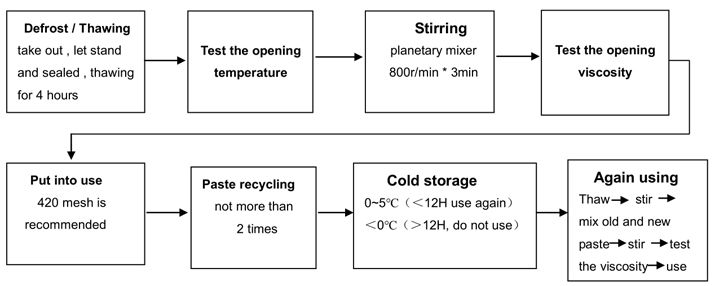

(6) It's recommended that the copper paste be placed in the ink mixing roomfor thawing for 4 hours, not more than 5 hours; If it has not been opened andput into use for more than 5 hours, it’s recommended to put them into the freezer for storage again.

(7) After thawing, the copper paste was stirred bya planetary mixer and then the viscosity was tested to be the most accurate.

(8) It’s recommended to use the copper paste within 8 hours after opening it. The unused part can be recycled for up to 2 times. If the paste viscosity increases due to paste recycling, please add new pastefor mixed use.

(9) Usage flow chart as below :

Remarks: silver content, solid content, conductivity and viscosity can be customized according to the actual needs of customers.

Disclaimer : The information provided in this Technical Data Sheet (TDS) is compiled in goodfaith and obtained using procedures performed at Mogreat Company to the best of ourknowledge. The information on this TDS has been updated on the date printed,and latest versions can be obtained upon request. The customer is responsiblefor conducting tests to determine whether our products are compatible with thecustomer’s process and specific applications.

URL: www.mogreat.com